Providing optimal solutions by taking on the challenge of diverse industrial fields

We, HIKARI Co., Ltd., propose fully customized value-added factory automation (FA) systems to meet automation needs in a wide range of industrial fields.

We improve production efficiency and bring new value to our clients’ businesses by designing and building systems optimized for each site.

We continue to solve problems in diverse industries with our flexible response and high technological capabilities.

Sales

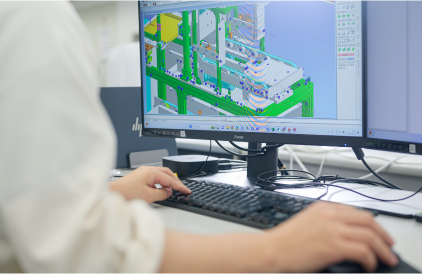

Design

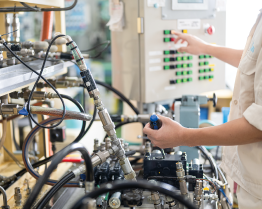

Control

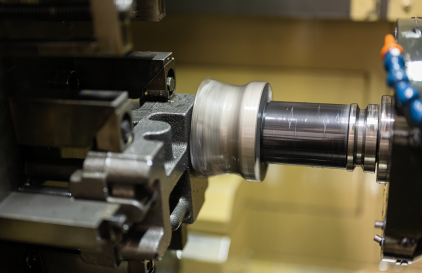

Machining

Material

Procurement

Assembly

Delivery

and Installation

Maintenance

We will ask the customer for the specifications of the equipment.

We will summarize each requirement, such as the environment in which it will operate and the characteristics of the object to be produced.

HIKARI will make proposals while recalling our areas of expertise and past achievements.

We aim to grasp needs without fail and make proposals that go beyond what the customer is looking for.

We consider various aspects such as equipment performance, price, takt time, defect rate, production cost, labor saving, and multi-product support. We then conceptualize a system and propose FA with high added value.

HIKARI’s control staff is involved from the facility design stage and builds control systems with efficiency, operability, and maintainability in mind.

HIKARI’s technology is used not only to operate the equipment but also to establish traceability.

We have a full range of processing machines and produce parts with high precision.

We have acquired ISO9001 certification for thorough quality control. We have our own machining department, which enables us to manufacture products with short delivery times.

We directly connect design data to the job site and perform assembly in real time.

Sub-unitization is promoted to increase efficiency and guarantee accuracy. We also unify the flow of products in one direction to ensure lean manufacturing and quality control.

We go to the factory where the customer produces to install the equipment that we have set up in-house.

After completion at the site, we have the equipment running so that the customer can use it to produce their products.

After that, we will respond to any problems or specification changes brought to our attention.

We are actively promoting DX and optimizing manufacturing through IoT technology. Furthermore, in order to maximize the use of digital technology, we produce related applications in-house. This allows us to be flexible and responsive, providing products that meet the diverse needs of our customers.

We aim to achieve sustainable growth by combining advanced production management with cost reduction through efficiency gains from DX and in-house production of proprietary technologies.

Research and development at HIKARI Co., Ltd. is at the core of creating the technologies and products of the future. Here, cutting-edge technological research and the realization of innovative ideas take place. Our engineers and researchers work together in R&D to develop new products and processes.

Our Technologies for Assembling the Future

~We offer a wide range of products,

from individual to assembly parts.~

We manufacture precision parts by machining, and assemble and test them, then deliver them as assembly parts. We have established a new production line that can handle not only mass production but also high-mix, low-volume production. We have also built an efficient production system by manufacturing machining jigs and tools and establishing our own automatic transfer and production system.

Our integrated system, from machining to assembly, enables us to manufacture products according to customer specifications. We can propose and provide quality, price, delivery, etc., that meet the customer’s requirements.

We use an in-house production management system to centrally manage production planning, progress management, inventory control, material procurement, etc., to ensure thorough control of delivery dates.

With more than 100 machines, we are capable of machining to suit the shape, size, and precision of the product. We have built our own design line to handle a wide range of products from high-mix, low-volume production to mass production.

We can perform inspections tailored to your needs, from partial measurements to whole number and whole item measurements.

We can link inspection reports with manufacturing instructions and promptly respond to retroactive and corrective actions.

We assemble machined products made in-house and purchased products to produce assembled products. We also design and manufacture assembly jigs in-house.

With our in-house-made test jigs and testing machines, we can perform tests that meet your specifications. We also have a wealth of past delivery records, so we can consult with our customers and respond to their needs.

Packing and shipping can be customized according to the customer’s needs. Since it is separated from the processing and washing areas, contamination can be prevented.

Because we have more than 100 machines, from stand-alone machines to line machines,

the production system can handle various lots and shapes.

MC1, 2, and 3 Lines

NC Line

MC fully automatic

No. 4 Line